उत्पाद विवरण:

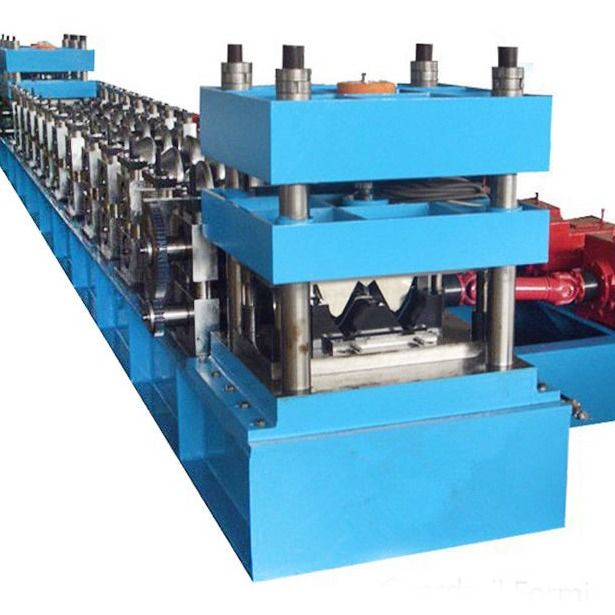

मेटल कोल्ड रोलिंग मिल एक उन्नत औद्योगिक मशीन है जिसे धातु सामग्री को सटीक और उच्च गुणवत्ता वाले तैयार उत्पादों में कुशलतापूर्वक संसाधित करने के लिए डिज़ाइन किया गया है। उपलब्ध विभिन्न प्रकारों में, फोर-हाई कोल्ड रोलिंग मिल धातु बनाने के अनुप्रयोगों में अपने असाधारण प्रदर्शन और बहुमुखी प्रतिभा के लिए विशेष रूप से उल्लेखनीय है। यह उपकरण बेहतर रोलिंग परिणाम देने के लिए इंजीनियर है, जो धातु की एक विस्तृत श्रृंखला और शीट के लिए लगातार मोटाई और बेहतर सतह परिष्करण सुनिश्चित करता है।

इस मेटल कोल्ड रोलिंग मिल में ड्राइव: ओ के रूप में दर्शाया गया एक मजबूत ड्राइव सिस्टम है, जो रोलिंग प्रक्रिया के दौरान सुचारू और स्थिर संचालन सुनिश्चित करता है। ड्राइव तंत्र को मांग वाले वर्कलोड को संभालने के लिए अनुकूलित किया गया है, जो रोलिंग गति पर विश्वसनीय बिजली संचरण और सटीक नियंत्रण प्रदान करता है। यह विश्वसनीयता तैयार ट्यूबों की गुणवत्ता और एकरूपता को बनाए रखने में महत्वपूर्ण है, जो इसे धातु कार्य उद्योगों में एक अपरिहार्य संपत्ति बनाता है।

इस कोल्ड रोलिंग मिल की प्रमुख विशिष्टताओं में से एक 168 मिमी से 325 मिमी तक बाहरी व्यास (ओडी) के साथ तैयार ट्यूबों का उत्पादन करने की क्षमता है। यह विस्तृत श्रृंखला विभिन्न औद्योगिक आवश्यकताओं को समायोजित करती है, जिससे निर्माता विविध बाजार मांगों को पूरा कर सकते हैं। मिल का सटीक इंजीनियरिंग इसे तंग सहनशीलता बनाए रखने की अनुमति देता है, जो उन अनुप्रयोगों के लिए आवश्यक है जहां आयामी सटीकता सर्वोपरि है।

तैयार ट्यूबों की कतरनी लंबाई को 1 से 12 मीटर के बीच समायोजित किया जा सकता है, जो विशिष्ट परियोजना आवश्यकताओं को पूरा करने के लिए उत्पादन में लचीलापन प्रदान करता है। कतरनी लंबाई की यह सीमा ऑटोमोटिव, निर्माण और मशीनरी निर्माण जैसे उद्योगों के लिए आदर्श है, जहां अनुकूलित ट्यूब लंबाई की अक्सर आवश्यकता होती है। संरचनात्मक अखंडता से समझौता किए बिना लंबी, निरंतर ट्यूबों का उत्पादन करने की क्षमता फोर-हाई कोल्ड रोलिंग मिल डिजाइन की दक्षता को उजागर करती है।

1000 टन (1000T) के अधिकतम रोलिंग बल के साथ, यह मेटल कोल्ड रोलिंग मिल धातु वर्कपीस पर पर्याप्त दबाव डालने में सक्षम है, जिससे मोटाई में कमी और धातु के गुणों का परिष्करण होता है। उच्च रोलिंग बल यह सुनिश्चित करता है कि सबसे कठिन धातुओं को भी प्रभावी ढंग से संसाधित किया जा सकता है, जिसके परिणामस्वरूप बढ़ी हुई ताकत और बेहतर सतह परिष्करण जैसे बेहतर यांत्रिक गुण होते हैं। यह इसे स्टील, एल्यूमीनियम और अन्य मिश्र धातुओं सहित विभिन्न धातुओं को रोल करने के लिए उपयुक्त बनाता है।

फोर-हाई कोल्ड रोलिंग मिल कॉन्फ़िगरेशन चार रोलों की व्यवस्था के कारण विशेष रूप से फायदेमंद है - दो छोटे वर्किंग रोल दो बड़े बैकअप रोल के बीच सैंडविच किए गए हैं। यह सेटअप उच्च दबाव रोलिंग के दौरान रोल विक्षेपण को कम करता है, धातु की पट्टी या ट्यूब की चौड़ाई में समान मोटाई सुनिश्चित करता है। नतीजतन, तैयार उत्पाद उत्कृष्ट चपलता और सतह की गुणवत्ता प्रदर्शित करते हैं, जो उच्च अंत विनिर्माण अनुप्रयोगों में महत्वपूर्ण कारक हैं।

अपनी यांत्रिक और परिचालन शक्तियों के अलावा, यह मेटल कोल्ड रोलिंग मिल रखरखाव में आसानी और ऑपरेटर की सुविधा को ध्यान में रखकर डिज़ाइन की गई है। इसका मजबूत निर्माण डाउनटाइम को कम करता है और उत्पादकता को बढ़ाता है, जबकि उपयोगकर्ता के अनुकूल नियंत्रण रोलिंग प्रक्रिया के दौरान सटीक समायोजन की अनुमति देते हैं। स्थायित्व और उपयोगिता का यह संयोजन मिल को धातु बनाने के संचालन के लिए एक लागत प्रभावी समाधान बनाता है।

कुल मिलाकर, मेटल कोल्ड रोलिंग मिल, विशेष रूप से फोर-हाई कोल्ड रोलिंग मिल प्रकार, आधुनिक धातु प्रसंस्करण तकनीक का शिखर प्रतिनिधित्व करता है। तैयार ट्यूब आकारों की एक विस्तृत श्रृंखला को संभालने की इसकी क्षमता, 1000T के शक्तिशाली अधिकतम रोलिंग बल के साथ संयुक्त, इसे निर्माताओं के लिए एक आदर्श विकल्प बनाती है जो उच्च गुणवत्ता, सुसंगत और कुशल कोल्ड रोलिंग समाधान चाहते हैं। चाहे 168 मिमी से 325 मिमी के बाहरी व्यास या 1 से 12 मीटर तक की कतरनी लंबाई के साथ ट्यूबों का उत्पादन करना हो, यह मिल प्रतिस्पर्धी धातु कार्य उद्योग में अपनी सटीकता, विश्वसनीयता और प्रदर्शन के लिए अलग है।

विशेषताएँ:

-

उत्पाद का नाम: कोल्ड रोलिंग मिल

-

स्ट्रेच टेंशन: 120KN

-

कास्ट रोलिंग मिल: 2-हाई Φ720×1450mm (टू-हाई कोल्ड रोलिंग मिल)

-

मॉडल विकल्प: 4-हाई, 6-हाई, 12-हाई, 20-हाई

-

तैयार पाइप मात्रा: 1

-

मोटर पावर: 110kw

-

स्टेनलेस स्टील कोल्ड रोलिंग मिल अनुप्रयोगों के लिए उपयुक्त

-

स्टील कोल्ड रोलिंग मिल प्रक्रियाओं के लिए डिज़ाइन किया गया

तकनीकी पैमाने:

|

मॉडल

|

4-हाई, 6-हाई, 12-हाई, 20-हाई

|

|

तैयार ट्यूब

|

एल

|

|

मोटर पावर

|

110 किलोवाट

|

|

मुख्य मोटर पावर

|

90 किलोवाट

|

|

अधिकतम रोलिंग बल

|

1000 टी

|

|

कास्ट रोलिंग मिल

|

2हाई Φ720×1450mm

|

|

त्वचा पास मिल

|

4Hi

|

|

स्ट्रेच टेंशन

|

120 केएन

|

|

प्रवेश चौड़ाई

|

≤175 मिमी

|

|

मशीन का वजन

|

मशीन कॉन्फ़िगरेशन के अनुसार

|

अनुप्रयोग:

हेंगली कोल्ड रोलिंग मिल लाइन धातु प्रसंस्करण उद्योग की विविध आवश्यकताओं को पूरा करने के लिए डिज़ाइन किया गया एक अत्याधुनिक समाधान है। चीन से उत्पन्न, यह उन्नत कोल्ड रोलिंग मिल लाइन 2-हाई Φ720×1450mm के विनिर्देशों के साथ एक कास्ट रोलिंग मिल और 4Hi की स्किन पास मिल को शामिल करती है, जो इसे विभिन्न अनुप्रयोगों के लिए एक आदर्श विकल्प बनाती है। उपकरण को 168 मिमी से 325 मिमी तक तैयार ट्यूब बाहरी व्यास को संभालने के लिए इंजीनियर किया गया है, जिसमें 175 मिमी तक की प्रवेश चौड़ाई क्षमता है, जो धातु उत्पादों की एक विस्तृत श्रृंखला के साथ संगतता सुनिश्चित करता है।

हेंगली कोल्ड रोलिंग मिल लाइन के प्रमुख अनुप्रयोग अवसरों में से एक उच्च गुणवत्ता वाली स्टील शीट और स्ट्रिप्स का उत्पादन है। फोर-हाई कोल्ड रोलिंग मिल कॉन्फ़िगरेशन मोटाई और सतह परिष्करण के सटीक नियंत्रण की अनुमति देता है, जो ऑटोमोटिव विनिर्माण, निर्माण और उपकरण उत्पादन जैसे उद्योगों में महत्वपूर्ण है। यह मिल लाइन विशेष रूप से पतली, समान स्टील स्ट्रिप्स के उत्पादन के लिए उपयुक्त है जिसका उपयोग ऑटोमोटिव बॉडी पैनल, घरेलू उपकरणों और संरचनात्मक घटकों में किया जाता है, जहां सतह की गुणवत्ता और आयामी सटीकता सर्वोपरि है।

इसके अतिरिक्त, हेंगली कोल्ड रोलिंग मिल लाइन गैर-लौह धातुओं, विशेष रूप से तांबे की स्ट्रिप्स के प्रसंस्करण में उत्कृष्ट है। कॉपर स्ट्रिप कोल्ड रोलिंग मिल क्षमताएं इसे विद्युत और इलेक्ट्रॉनिक अनुप्रयोगों के लिए आवश्यक बेहतर सतह परिष्करण और यांत्रिक गुण प्रदान करने में सक्षम बनाती हैं। इस मिल लाइन के साथ लुढ़की हुई तांबे की स्ट्रिप्स का व्यापक रूप से ट्रांसफार्मर, विद्युत कनेक्टर और विभिन्न इलेक्ट्रॉनिक घटकों के निर्माण में उपयोग किया जाता है, जहां सामग्री की स्थिरता और प्रदर्शन महत्वपूर्ण हैं।

हेंगली कोल्ड रोलिंग मिल लाइन की बहुमुखी प्रतिभा विभिन्न उत्पादन वातावरण में इसकी अनुकूलन क्षमता तक फैली हुई है। चाहे बड़े पैमाने पर औद्योगिक संयंत्रों में या विशेष धातु प्रसंस्करण कार्यशालाओं में, मशीन के वजन और कॉन्फ़िगरेशन को परिचालन आवश्यकताओं के अनुसार अनुकूलित किया जा सकता है। यह लचीलापन निर्माताओं को दक्षता और उत्पाद की गुणवत्ता के लिए अपनी उत्पादन लाइनों को अनुकूलित करने की अनुमति देता है, जिससे हेंगली कोल्ड रोलिंग मिल आधुनिक धातु कार्य उद्योगों में एक अपरिहार्य संपत्ति बन जाती है।

संक्षेप में, चीन से हेंगली कोल्ड रोलिंग मिल लाइन स्टील शीट उत्पादन, कॉपर स्ट्रिप रोलिंग और सटीक धातु प्रसंस्करण सहित अनुप्रयोग परिदृश्यों की एक विस्तृत श्रृंखला में कार्य करती है। इसका फोर-हाई कोल्ड रोलिंग मिल डिज़ाइन, मजबूत कास्ट रोलिंग घटकों और 4Hi स्किन पास मिल के साथ संयुक्त, विभिन्न धातु प्रकारों और मोटाई श्रेणियों में असाधारण प्रदर्शन सुनिश्चित करता है। यह इसे उन उद्योगों के लिए एक पसंदीदा विकल्प बनाता है जो विश्वसनीय, उच्च गुणवत्ता वाले कोल्ड रोलिंग समाधान चाहते हैं।

पैकिंग और शिपिंग:

कोल्ड रोलिंग मिल के लिए उत्पाद पैकेजिंग और शिपिंग

कोल्ड रोलिंग मिल को ग्राहक को सुरक्षित परिवहन और डिलीवरी सुनिश्चित करने के लिए सावधानीपूर्वक पैक किया जाता है। मिल के मुख्य घटकों को पारगमन के दौरान नमी, धूल और प्रभाव से होने वाले नुकसान को रोकने के लिए सुरक्षात्मक सामग्री जैसे बबल रैप, फोम पैडिंग और वाटरप्रूफ शीट के साथ सुरक्षित रूप से लपेटा जाता है।

भारी और भारी भागों को मजबूत लकड़ी के क्रेट या धातु के फ्रेम में रखा जाता है, जो स्थिरता बनाए रखने के लिए स्टील स्ट्रैप से प्रबलित होते हैं। छोटे घटकों और एक्सेसरीज़ को कुशनिंग सामग्री के साथ लेबल वाले बक्सों में पैक किया जाता है ताकि किसी भी प्रकार की गति या टूट-फूट से बचा जा सके।

उपयोग की जाने वाली सभी पैकेजिंग सामग्री पर्यावरण के अनुकूल हैं और अंतर्राष्ट्रीय शिपिंग नियमों का अनुपालन करती हैं। पैकेजिंग को क्रेन या फोर्कलिफ्ट का उपयोग करके आसान लोडिंग, अनलोडिंग और हैंडलिंग की सुविधा के लिए डिज़ाइन किया गया है।

शिपिंग के लिए, कोल्ड रोलिंग मिल को कंटेनर शिपिंग, फ्लैटबेड ट्रकों या विशेष भारी कार्गो वाहक के माध्यम से गंतव्य और ऑर्डर के आकार के आधार पर ले जाया जाता है। प्रत्येक शिपमेंट के साथ पैकिंग सूची, हैंडलिंग निर्देश और मूल प्रमाण पत्र सहित विस्तृत प्रलेखन होता है।

हमारी रसद टीम समय पर डिलीवरी सुनिश्चित करने और शिपिंग प्रक्रिया के दौरान ट्रैकिंग जानकारी प्रदान करने के लिए ग्राहकों के साथ मिलकर काम करती है। आगमन पर, हमारी टीम कोल्ड रोलिंग मिल के इष्टतम प्रदर्शन की गारंटी के लिए स्थापना और कमीशनिंग के लिए सहायता प्रदान करती है।

अक्सर पूछे जाने वाले प्रश्न:

Q1: कोल्ड रोलिंग मिल का ब्रांड नाम क्या है?

A1: कोल्ड रोलिंग मिल का निर्माण हेंगली द्वारा किया जाता है, जो धातु प्रसंस्करण उद्योग में एक विश्वसनीय ब्रांड है।

Q2: हेंगली कोल्ड रोलिंग मिल का उत्पादन कहाँ होता है?

A2: हेंगली कोल्ड रोलिंग मिल चीन में बनाया गया है, जो उच्च गुणवत्ता वाले विनिर्माण मानकों को सुनिश्चित करता है।

Q3: हेंगली कोल्ड रोलिंग मिल का उपयोग करके किन सामग्रियों को संसाधित किया जा सकता है?

A3: हेंगली कोल्ड रोलिंग मिल को स्टील, स्टेनलेस स्टील और एल्यूमीनियम शीट सहित विभिन्न धातुओं को संसाधित करने के लिए डिज़ाइन किया गया है।

Q4: हेंगली कोल्ड रोलिंग मिल के विशिष्ट अनुप्रयोग क्या हैं?

A4: इस कोल्ड रोलिंग मिल का उपयोग आमतौर पर ऑटोमोटिव, निर्माण, उपकरण निर्माण और धातु निर्माण जैसे उद्योगों में किया जाता है।

Q5: हेंगली कोल्ड रोलिंग मिल किस क्षमता या मोटाई रेंज को संभाल सकती है?

A5: हेंगली कोल्ड रोलिंग मिल विभिन्न प्रकार की मोटाई को संभाल सकती है, आमतौर पर 0.1 मिमी से 3.5 मिमी तक, विशिष्ट मॉडल पर निर्भर करता है।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!